Our Services

We offer a range of machining services to the civil, mining and agricultural industries of the Central Highlands from our centrally located workshop in Emerald.

We aim to always deliver quality, precision work on budget and on time. Our qualified, highly experienced team of machinists pride themselves on listening to the customer, understanding their needs, focusing on the solution and executing the job to a high standard in the most efficient manner possible.

Our team at Ryder Machining Services are problem solvers who aim to extend the life of a machine with thorough scheduled maintenance work or reclamation of a part, help a valued customer meet a deadline with the manufacture of replacement parts or come up with a practical and affordable solution that gets their piece of equipment back up and running as quickly as possible.

Our main areas of service are:

Part Reclamation

Over the course of a machine’s lifecycle, major components must be replaced to ensure continued optimal performance. Replacing major components with brand new Original Equipment Manufacturer (OEM) parts can be costly and is reliant on components being readily available. The result can be unexpected downtime while waiting for new parts or a cost-blowout.

We regularly work with our customers to reclaim and rebuild components, helping to quickly get the machine back to work and also reduce the total lifecycle cost of mining and earthmoving equipment without compromising quality, performance, and reliability.

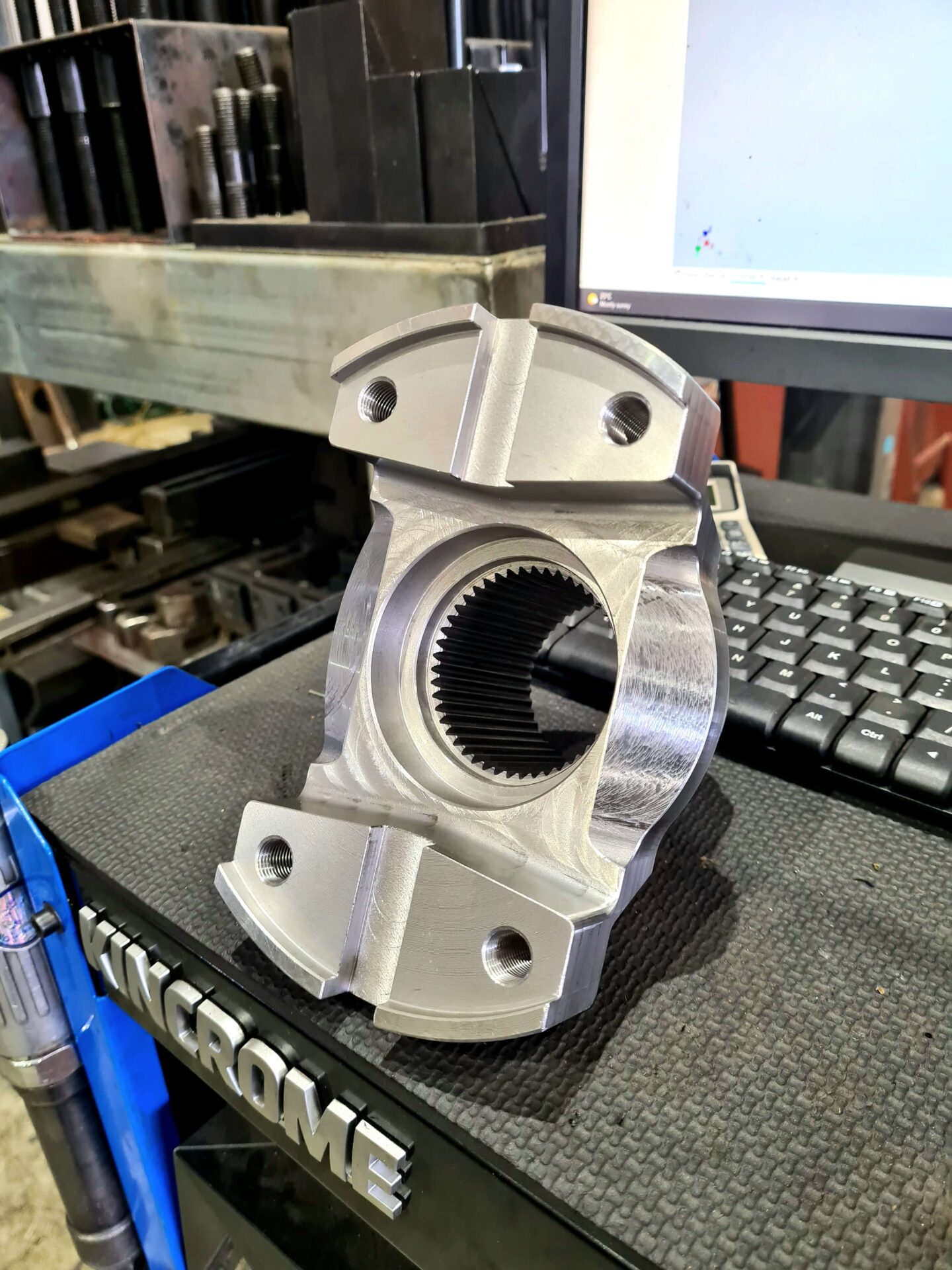

Part Manufacture

Our parts manufacturing services are largely driven by customers needing a worn or damaged part replaced sooner and more cost effectively than they can get it from the Original Equipment Manufacturer (OEM). Modification of the part is also a common request.

Through reverse engineering or manufacturing from a sample, our skilled team can quicky and efficiently create new parts and get the machine back up and running.

With years of experience our qualified tradesmen can determine the production techniques used in the manufacture of a part and identify the materials it is comprised of and in doing so, can re-manufacture equipment that is identical and often more suitable than the original.

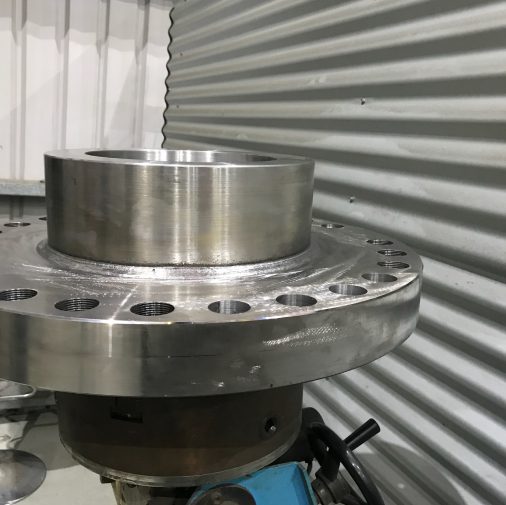

General Machining

From one-off parts to multiple production runs, our large and functional workshop houses an array of specialist equipment that enables us to find a solution to most of our customers varied requests.

Our current capabilities are:

Turning – up to 900mm DIA and up to 4 meters between centres

Milling – 4 meter bed with a 7 tonne capacity

Horizontal Boring – up to 2.5m x 2.5m and up to 10 tonne capacity.

The main equipment we use are:

- Manual and CNC Lathes

- Universal Mills

- CNC Bed Mills

- CNC Machining Centres

- CNC Horizontal Borer

- CNC Band Saws

- Slotters

- Surface grinders

- Geared head drills and turret mills

- Radial Arm Drills

We also stock a variety of commonly used materials including:

- Round, square or hex bar in mild steel, 4140 high tensile steel and stainless steel.

- Hollow bar in various sizes

- Bronze round and hollow bar

- Nylon round bar

Anything we don’t have on hand, we have great reliable suppliers who can supply the required material usually overnight.

Service Exchange Parts

Whether for planned maintenance or in times of emergency break down, we can supply components to suit most major Original Equipment Manufacturer (OEM) heavy mining equipment.

You simply purchase the re-manufactured component and forward the failed item to us. We re-engineer your component to original equipment specifications, incorporating the latest in design improvements, and it is returned to stock to fulfil the next customer order.

The only difference between new and re-manufactured components is in the price. We ensure an equivalent level of performance and reliability to that of brand-new components.

Liquid Nitrogen Service and Supply

Liquid Nitrogen is essential for the safe and accurate fitment of your bearings, pins, bushes etc, to ensure the maximum life of the equipment. This specific gas is an invaluable tool to ensure the confidence of reliable and accurate fitment saving both time and money.

We manufacture Liquid Nitrogen in-house and can supply in convenient and easily transportable 35L and 50L Dewars.

We can also supply custom made-to-order eskies to use the liquid nitrogen safely and easily.

Contact Us

Give us a call, send us an email or visit our workshop to see how we can help you with your machining needs.

- Mon - Fri 6:00am - 5:00pm

Sat and Sun - CLOSED - (07) 4982 4334 | 0488 085 238

- info@rydermachining.com.au

- 6 McCosker Street

Emerald QLD 4720

GET IN TOUCH